Where Customer Experience

Meets Quality Machining

A Manufacturing Team You Can Rely On

At Fidelity Manufacturing Group we make it our mission to provide an unparalleled experience for people seeking an honest, reliable, and helpful source for their machining and tooling needs. Whether it’s mould making, CNC machining, or anything in between, we pride ourselves on staying true to our word and doing whatever it takes to get the job done right.

learn moreExplore our divisions

Aerospace

Manufacturing

Our comprehensive facility, robust project planning, and quality assurance program allow us to offer the highest-grade machine solutions in the industry.

learn more

Machine & Mould

Solutions

As one of the most advanced machine shops in Western Canada, our products are manufactured to the highest standard - no matter how large or small the project.

learn more

Medical

Manufacturing

As specialists in manufacturing medically approved products, we use our expertise to work with health regulated protocols and safety procedures.

learn more

Why Choose Fidelity?

Innovation

We never shy away from a challenge and work to develop unique solutions for our customers.

Experienced Project Management

Fidelity has a large team with dedicated roles and project support staff who specialize in each area.

Unparalleled Quality

Our dedicated quality control processes and organizational culture help us to stay committed to quality.

What We Do Best

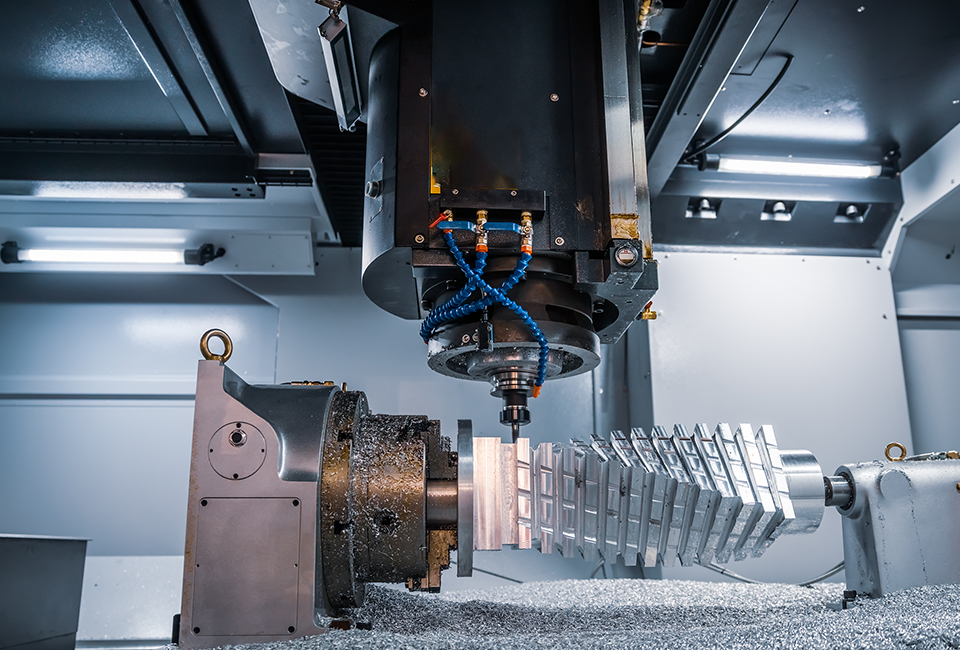

CNC Machining

Our team has the capabilities and know-how to machine the toughest, most intricate CNC jobs efficiently and accurately.

Mould Making

From high performance injection moulding to cable overmould manufacturing, our specialists use their expertise to ensure the highest quality moulds.

EDM

Our strategic and innovative approach allows us to handle a wide variety of hole drill, sink and wire EDM projects.

Design and Engineering

As your trusted manufacturing partner we put the utmost care into designing and engineering the best solution for your needs.

Oil Field Threading

We use an innovative oil field threading solution that measures and verifies the individual features and accuracy of each and every thread.

Medical Manufacturing

Whether it's meeting urgent deadlines or working within health regulated protocols, we have the skills and expertise to produce high quality medical products.